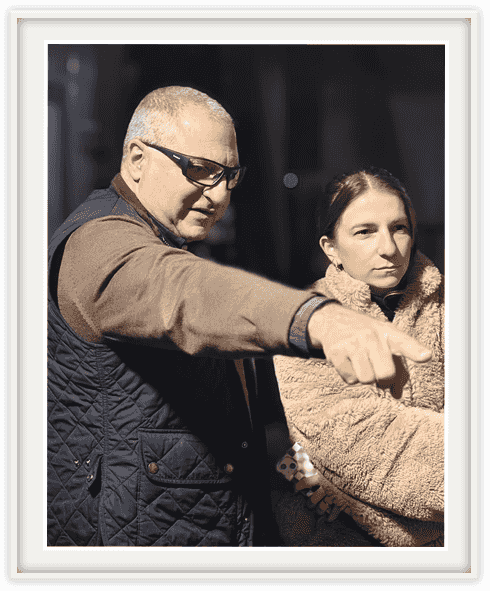

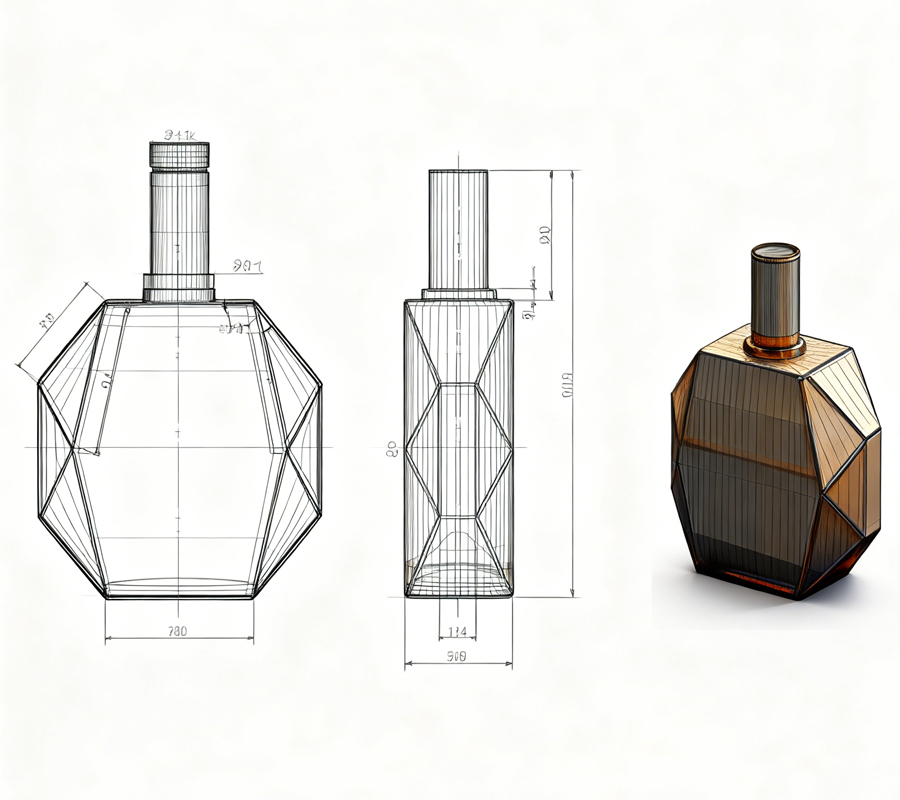

Design

First, the design determines the aesthetics, function and production cost of the final bottle

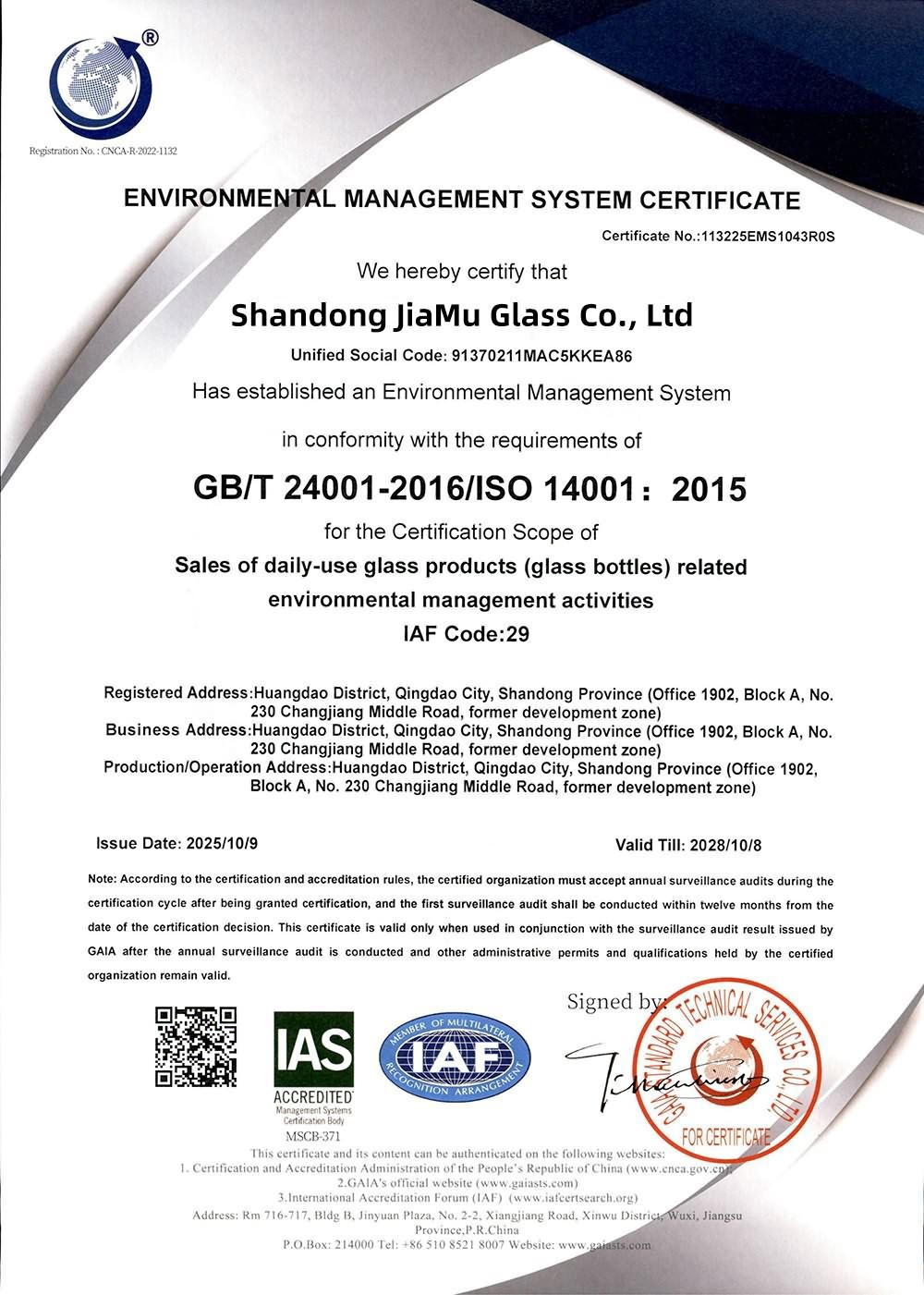

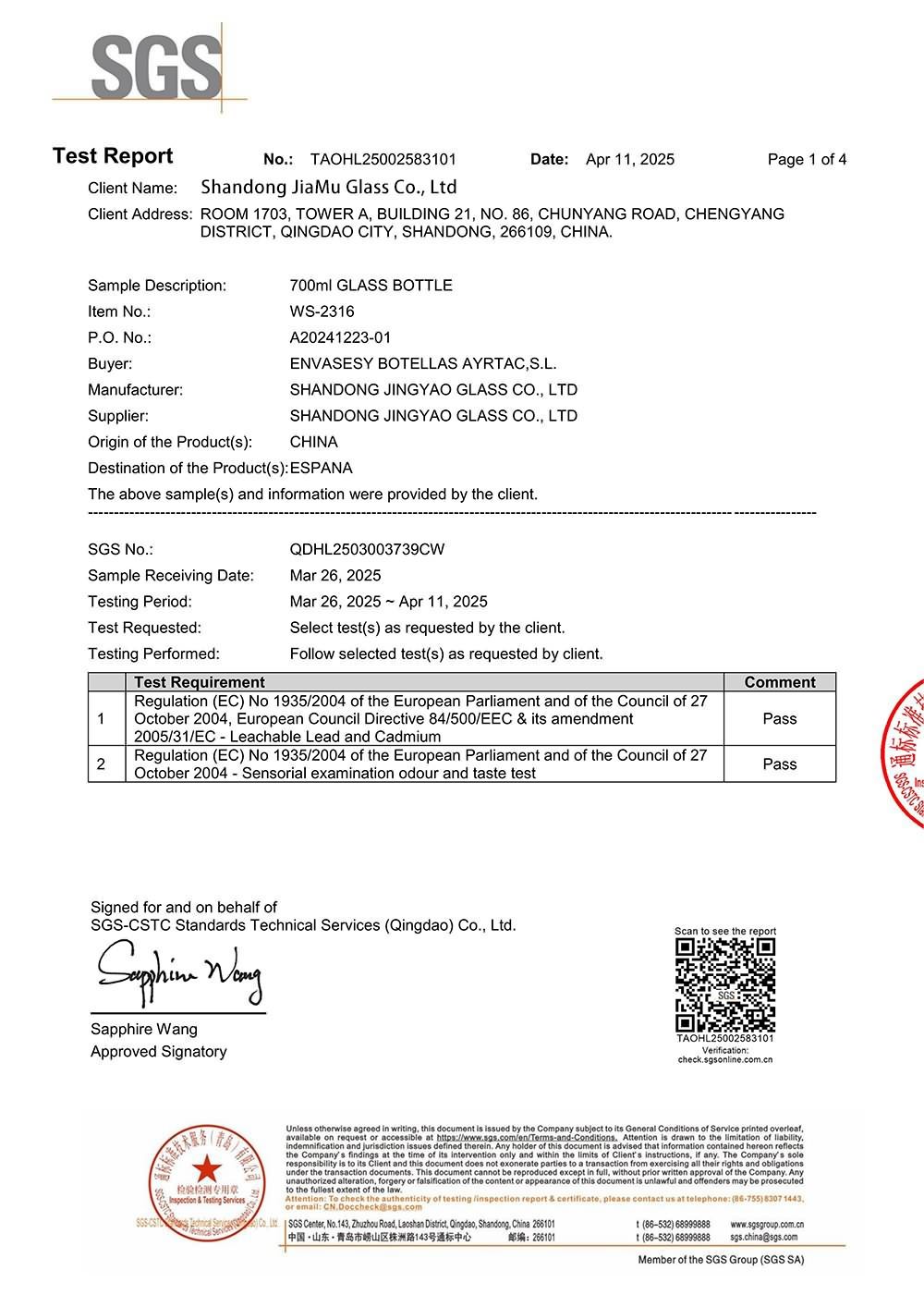

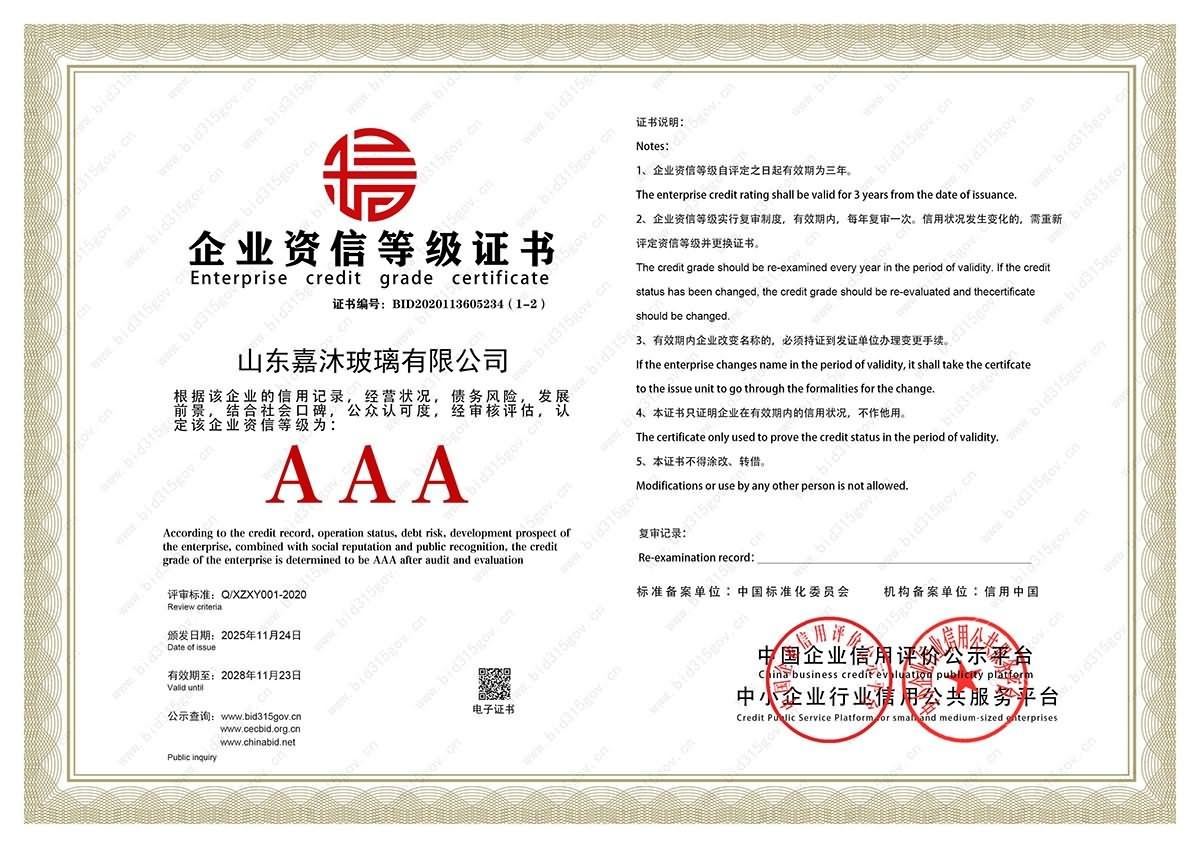

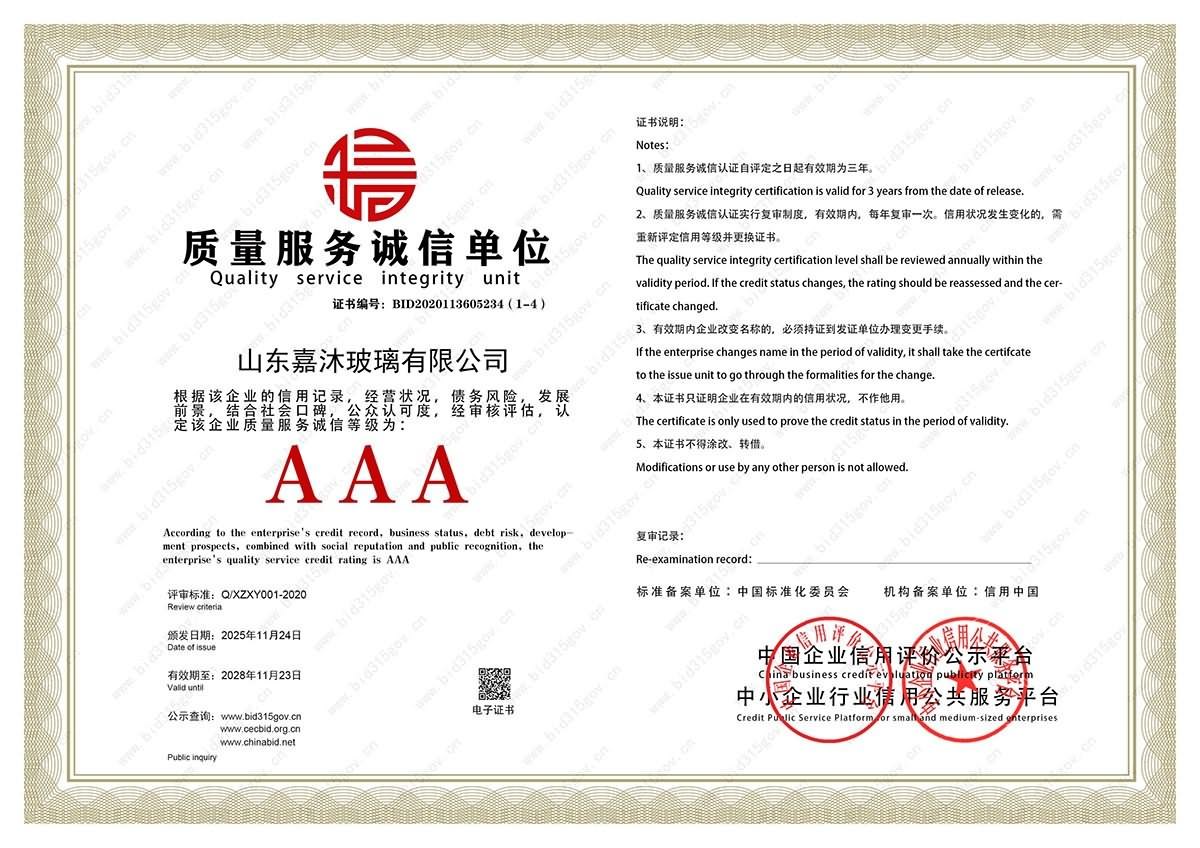

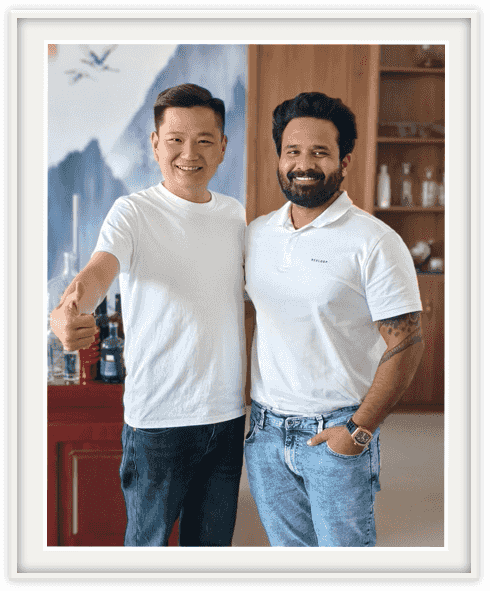

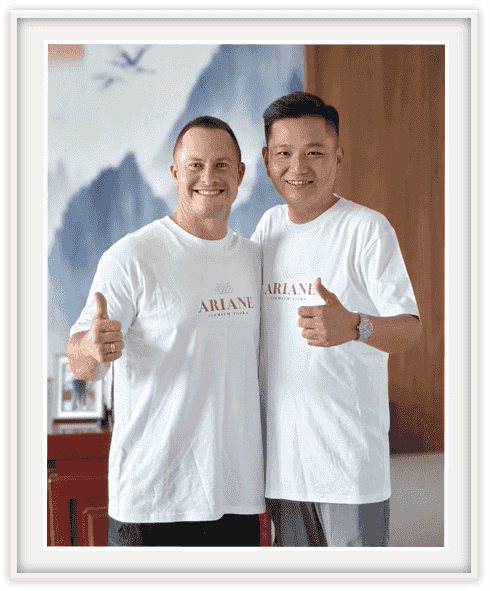

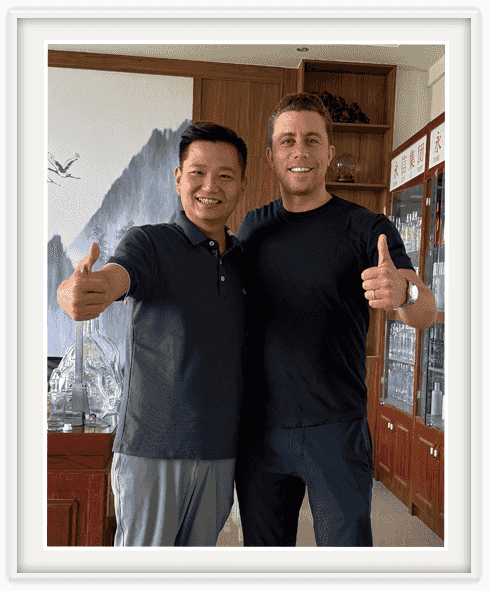

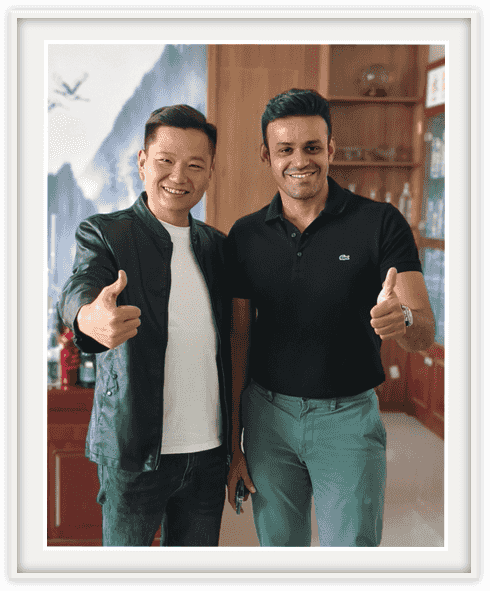

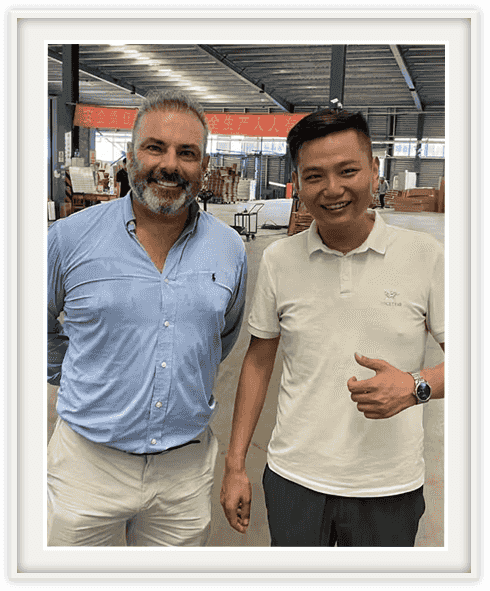

JiaMu Glass Group entered the glass packaging industry in 2015 and has focused on its core business for over a decade. Throughout its development, the company has continuously explored and innovated, constantly improving its production processes and management models, resulting in increasingly stable & reliable product quality, and gradually gaining international market recognition.

JiaMu Glass Group holds controlling stakes in several subsidiaries, including Tianjin YongXin Glass , New Tenda Glass, J·Y Glass, Shandong ChunSe Industry & Trade, and JiaMu Mould. Leveraging its group advantages, JiaMu Glass Group has built a complete industrial chain, integrating product design, 3D sample making, mold making, bottle manufacturing, and deep processing into a comprehensive commercial model.

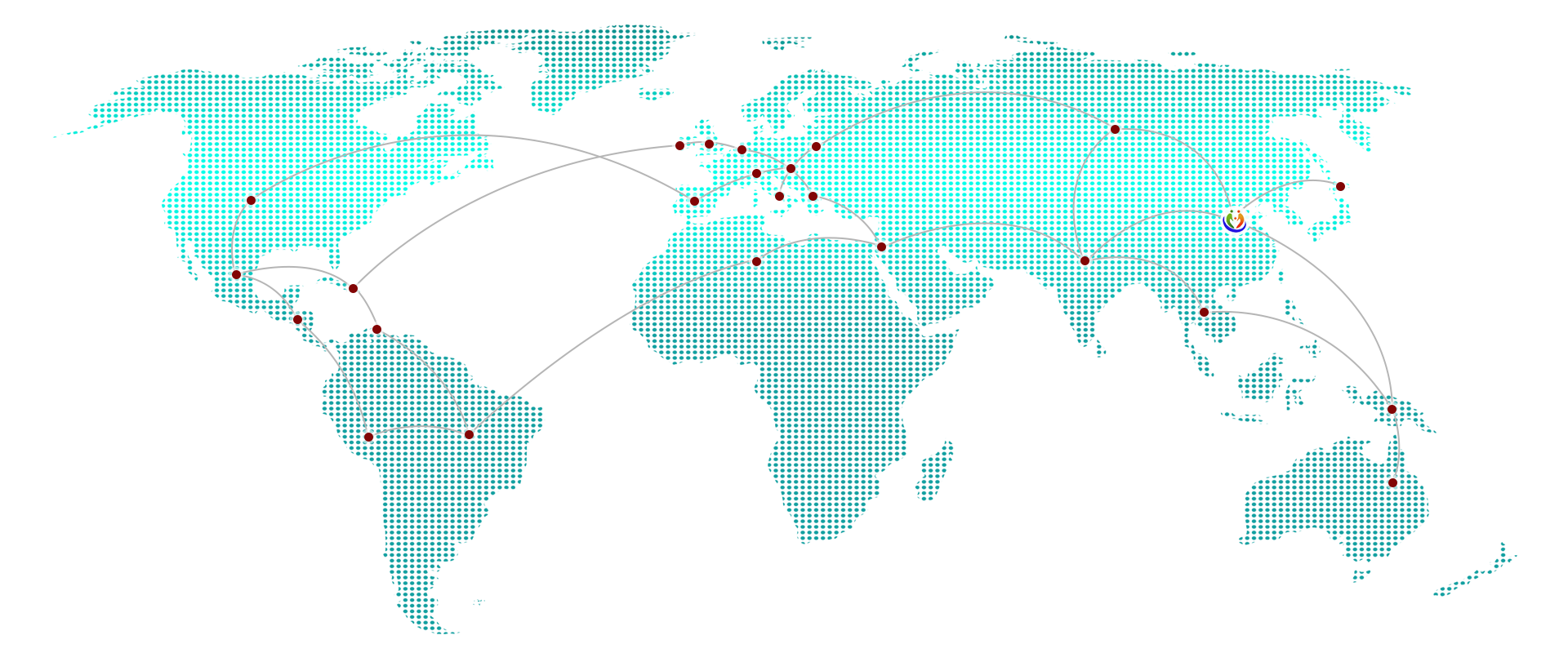

Currently, JiaMu Glass Group’s products have been exported to more than 20+ countries and regions worldwide, including the United States, the United Kingdom, Australia, the Netherlands, and New Zealand, Peru, Mexico, etc., holding an important position in the international glass packaging market.

In the future, JiaMu Glass Group will continue to uphold the philosophy of "quality first, innovative development," continuously enhancing its core competitiveness, expanding domestic and international markets, and striving to become a leading enterprise in the global glass bottle packaging industry, providing customers with superior products and better services.

7 Glass Bottle Production Plants in China

2 Decoration Factories in China

4 Glass Processing Centers in China

We make more than 2 Billion Glass Bottles each year

First, the design determines the aesthetics, function and production cost of the final bottle

Bottle design with relief, marking area and other details to check the feasibility of the project

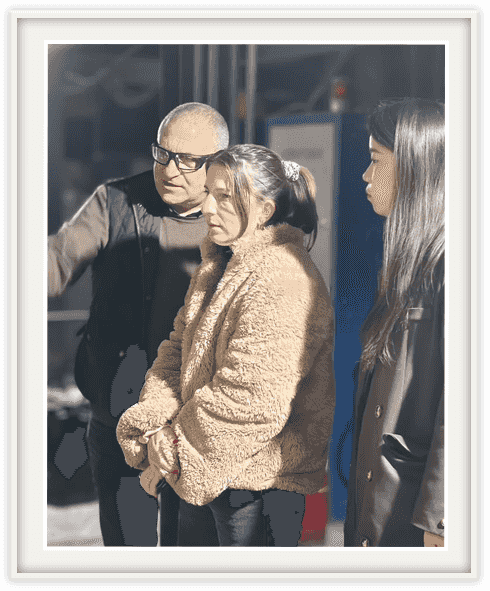

Mold manufacturing involves several processes, including cutting and grinding, assembly and polishing

Engineers must ensure that the production process is efficient, cost effective, and produces high quality bottles